Restoring Classic Carousel Cart Machines

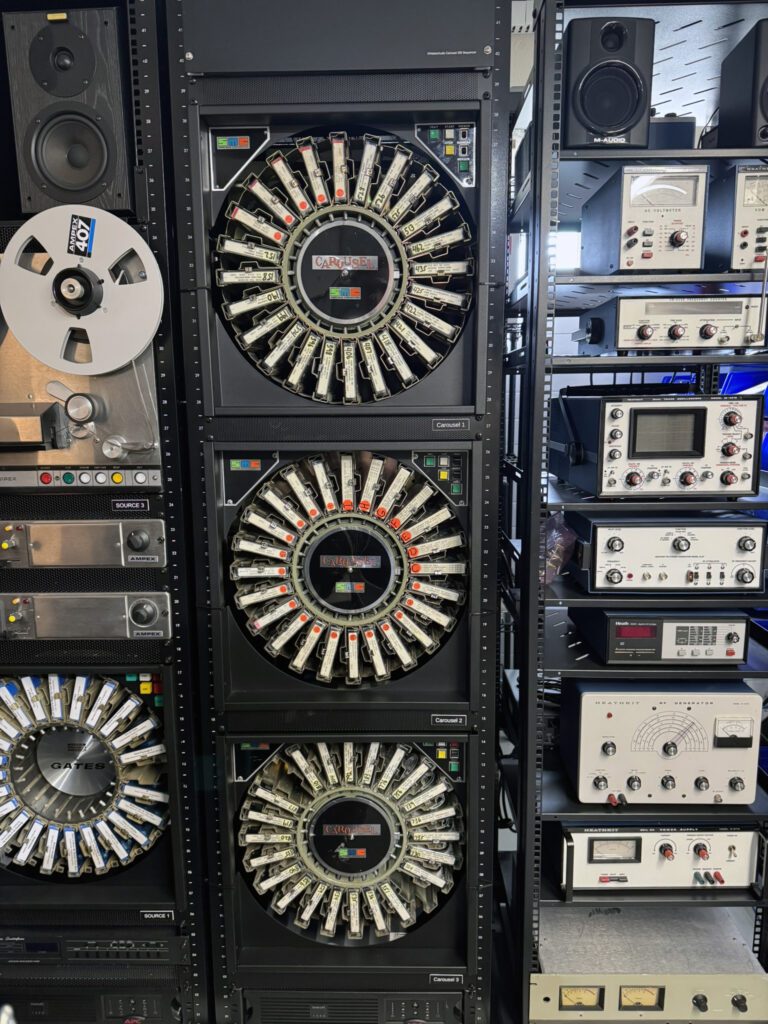

The Carousel cart machine was a staple of radio station automation systems in the 1970s and 80s. It provided the means to play back a large number of tape cartridges without operator intervention. The Carousel (shown above from a catalog listing) was manufactured by SMC (SonoMag Corp.) of Bloomington, IL, beginning in about 1968. The device could hold 24 cartridges that were played sequentially—or through optional equipment—in any random order. A single Carousel machine could not play carts back-to-back due to the required re-cuing of the cartridge, and the mechanical action needed to move one cart out of the playback unit and another cart in. With two Carousel machines, however, they could ping-pong back-and-forth forever.

There were a number of high-capacity cartridge playback machines in the early days of radio automation. The Carousel defined the “one tape head” class whereby an inventory of cartridges was moved (by various means) to a single playback device that included the tape heads and capstan/pinch roller assembly.

A second class of multiple playback devices approached the task from a different perspective. Rather than move the cartridges to a single playback unit, a playback device was provided at every cartridge position. The IGM (International Good Music, Bellingham, WA) Instacart defined this class of machine. The Instacart would hold 48 cartridges and play them in any random order, back-to-back. This was accomplished by having a single capstan motor for each bank of 12 cartridge positions (four banks in all for a total of 48 carts). Each position had a playback head and pinch roller/solenoid to engage and play the cartridge. The audio for each position was switched into a single output stream. The Instacart was a maintenance challenge, with all those tape heads and capstan positions to clean. However, since the workload of the Instacart was spread over 48 elements, the actual wear on each playback unit was relatively small.

The Carousel and the Instacart represented the two ends of multi-playback technologies. In between, there were variations on each theme, suited to individual use cases and price points.

It came to pass that three SMC 350 Carousel cart machines were offered for sale by a radio station not far from me. The price was reasonable and shipping costs were not prohibitive. I had already acquired and refurbished one 250 as part of the 1970s Automation System project documented in another blog. I had found the 250 to be reliable and well-built. The 250 and 350 are similar, the major difference being the use of digital logic devices to control the deck in the 350 rather than a relay-based system as used in the 250.

And so the project began.

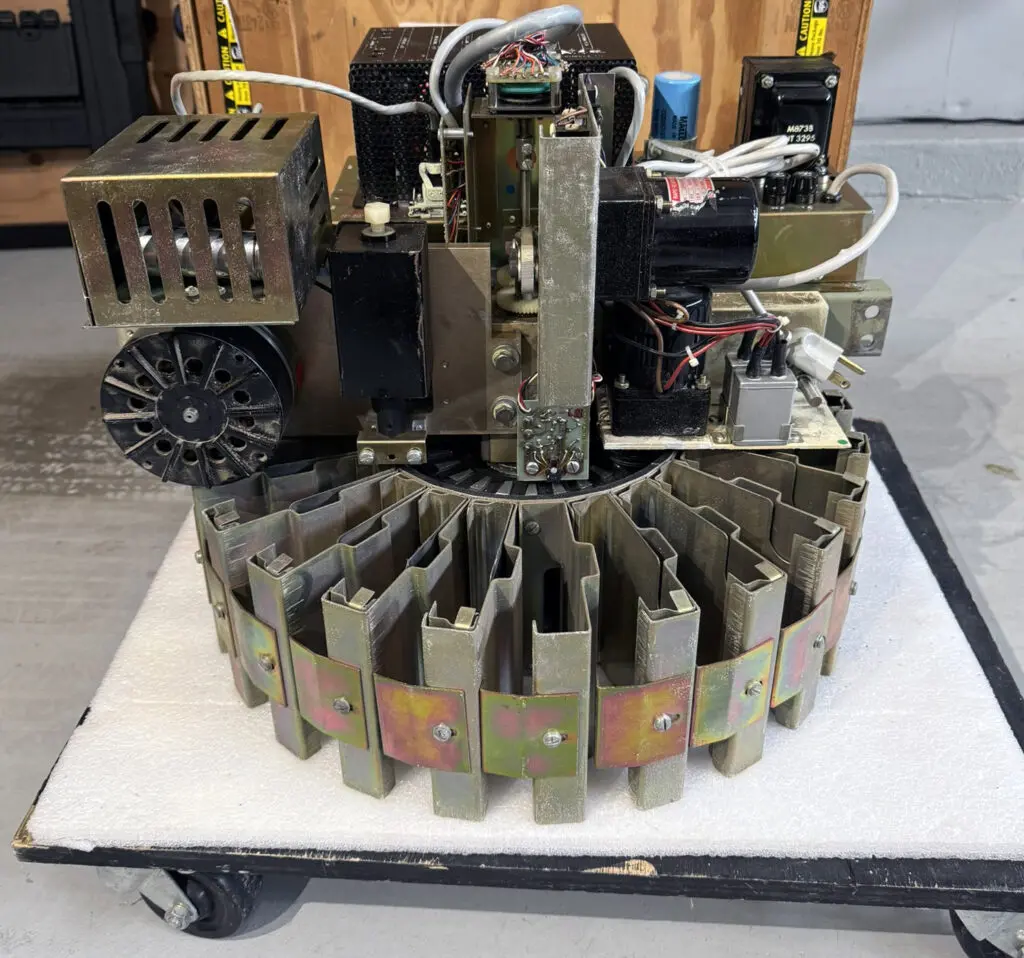

Like all of my projects, this one started with shipping crates full of stuff. The first challenge was getting the machines in a position where I could work on them. Each Carousel machine weighs about 95 pounds, and so moving one around (let alone three) is a challenge. Due to the weight of the 350, special considerations apply to mounting in a rack. A mounting bracket is required on each side of the machine and preferably secured at the front and rear of the rack. Not all racks will accommodate those brackets and so a custom bracket was designed and manufactured by Protocase.

The physical layout of the 350 makes it difficult to do much work on the assembly unless mounted in its operating position. The project was therefore delayed until the mounting brackets and companion rack were available.

In the meantime, an assessment was made of the three machines. All appeared to be in good physical condition, with all parts intact. The most significant issue identified was a bent mounting frame on one of the machines. This would be difficult to address. As it turned out, the machine performed correctly without any repair, which was good since straightening the frame would have been difficult (perhaps impossible) to accomplish.

The front panel covers were removed and sent to a local shop to be sanded and given a new powder-coat finish. The covers are shown below after removal from the shipping containers. Control switches can be seen in the upper right corner of the covers. Some of the switches were damaged and needed to be replaced.

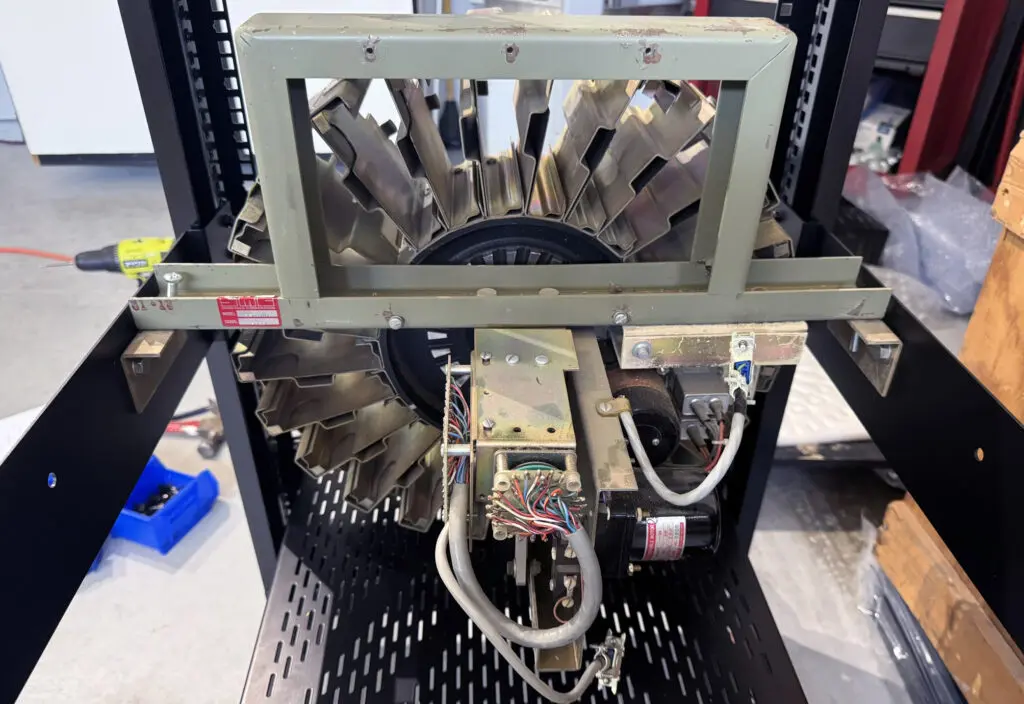

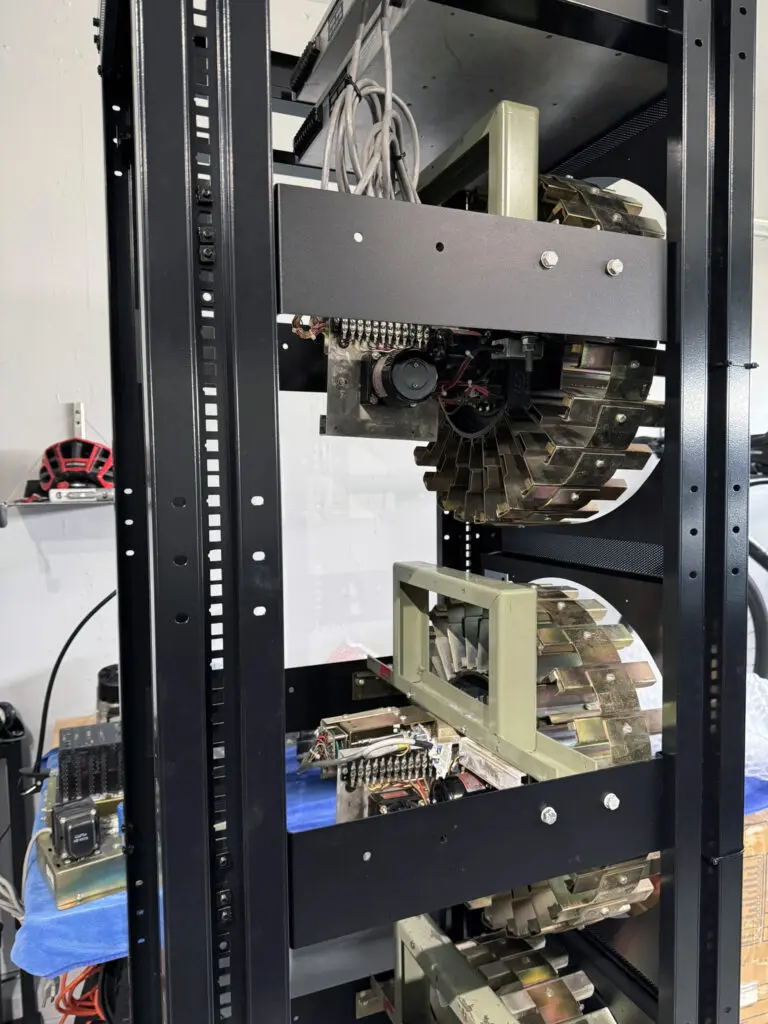

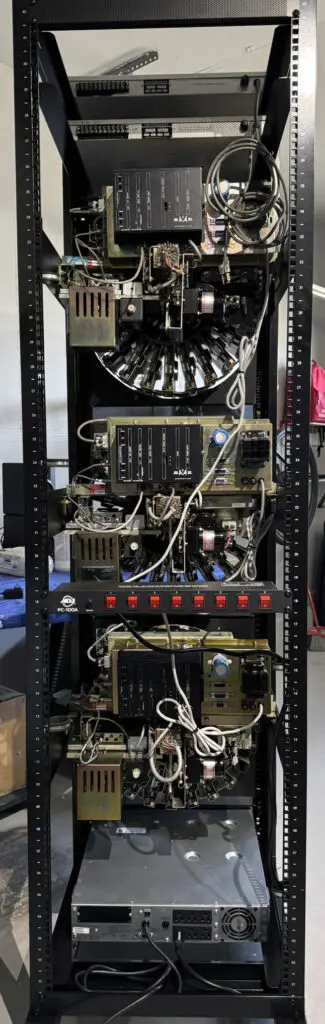

With delivery of the 42 RU rack and custom mounting brackets, the first Carousel machine was installed in the operating position. The brackets fit perfectly. They were designed to be interchangeable; i.e., the same bracket can be used on the right side and left side, which reduced the production cost significantly.

To facilitate installation of the machine in the rack, the two major subassemblies were removed, namely, the tape playback deck and the electronics chassis. This made the assembly considerably lighter and easier to maneuver into position.

The Carousel deck as viewed from the rear of the rack is shown below.

With the electronics chassis and tape playback deck removed, each unit was inspected and repaired as needed.

After a through cleaning of the main assemblies, the three machines were mounted in the rack, as shown below.

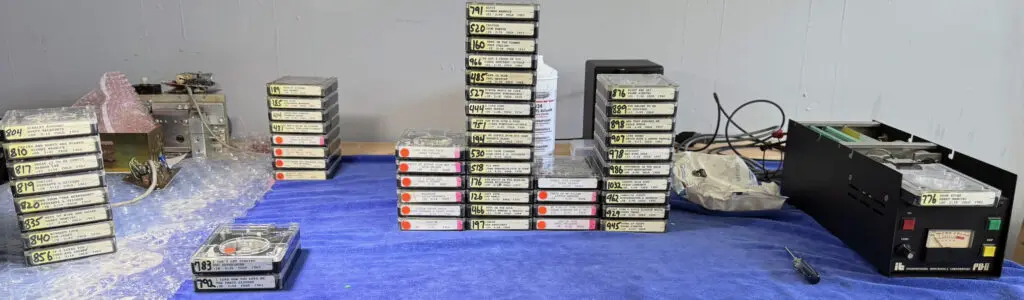

In order to use the Carousel machines it is necessary, of course, to have tape cartridges. In a lucky coincidence, I found a station in Las Vegas that was looking to clear out a storage space full of ScotchCart tape cartridges.

The ScotchCart was a great device; innovative for its time. Some decades later, however, the type of tape used in many (maybe most) of these carts suffers from the “sticky shed syndrome,” as described in another blog on this site. Fixing the cartridges is not difficult, but can be time-consuming. And, unfortunately, some carts (usually longer length units) cannot be recondition. The process for reconditioning ScotchCarts is described in the blog mentioned above. A lot of cartridges being processed for use can be seen in the photo below.

With the Carousel decks fully loaded with carts, work on the machines themselves continued.

In a major step forward, power was applied to the three machines for the first time in many years (or more likely, decades). When first powering up any piece of vintage electronics equipment, a number of things can go wrong—sometimes dramatically so. This time, however, all three decks passed the basic tape-handling tests, notably tray insertion, removal, and rotation. There was some concern about one of the decks because of a bent frame (as noted above) that presumably happened during shipping at some point in the past. Fortunately, the tape handling mechanisms of all three decks worked as intended.

Initial tests indicated some issues with the cue detector boards on two of the machines, which were addressed without any major work. In general, all machines handle the cartridges as intended, which was a big relief.

In parallel with the mechanical restoration of the Carousel decks, work was undertaken to interface the three decks with a sequencer that would allow for unattended operation. The sequencer utilizes the EOM signal to activate the next deck, and switch the audio output accordingly. The sequencer consists of three interface PCBs that manage operation of the decks, and a pair of power supply boards. The boards are contained in a card frame, as shown below.

A separate control panel is used to manage operation of the sequencer, as shown below. Operational modes include manual and sequencing of the decks in various patterns (1-2-3, 1-2, 1-3, 2-3).

After a fair amount of work, the three Carousel machines were returned to working order and interfaced with the sequencer to provide a simple automated playback system. The system, as installed, is shown below.

This was a long, expensive project…but a lot of fun too.