ScotchCart Repair

The NAB-type cartridge recorder/player was a critical element of any 1970s vintage radio studio. Cartridges of various lengths were available, the most popular of which were probably 40 second, 70 second, 2.5 minute, and 3.5 minute. Other lengths were sold, up to a maximum of 31 minutes for the largest type of cartridge. There were a number of cartridge brands during this era, notably Fidelipac, Audiopak, and ScotchCart. All shared the same basic form-factor, as defined in a standard developed by the National Association of Broadcasters (NAB).

The Fidelilpac and Audiopak designs were similar—a loop of tape of defined length was wound on a hub and routed past openings in the rear of the cartridge shell to accommodate interface with the cart machine record head, playback head, and pinch roller/capstan. The tape was held against the heads by foam rubber pads, ensuring adequate contact between the tape and the head.

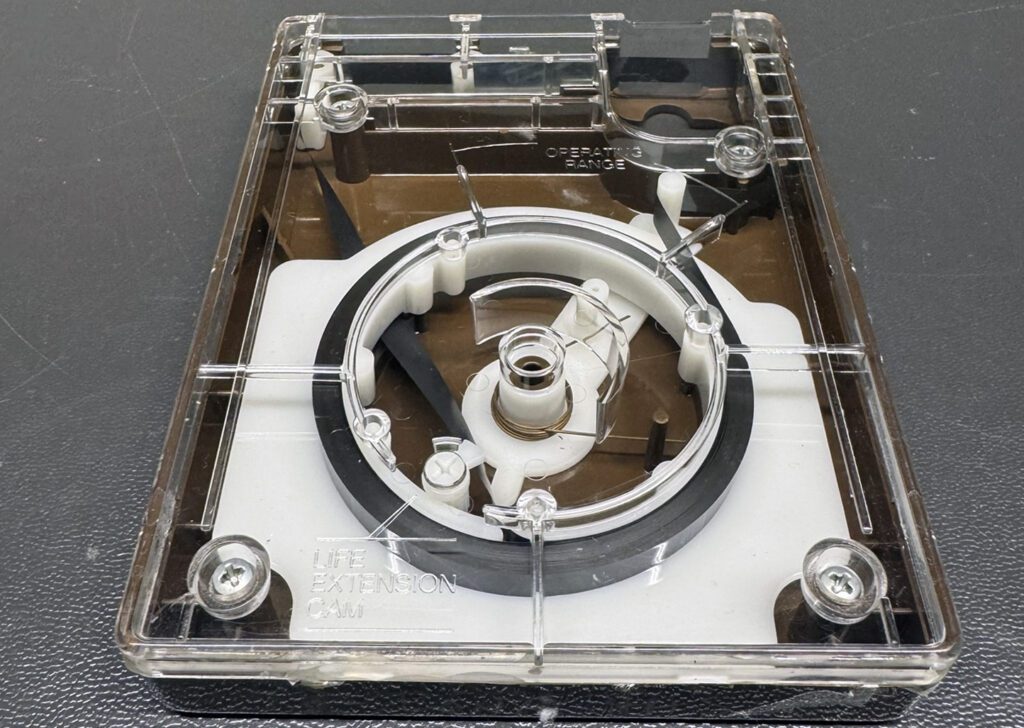

The ScotchCart (shown below) was a little different.

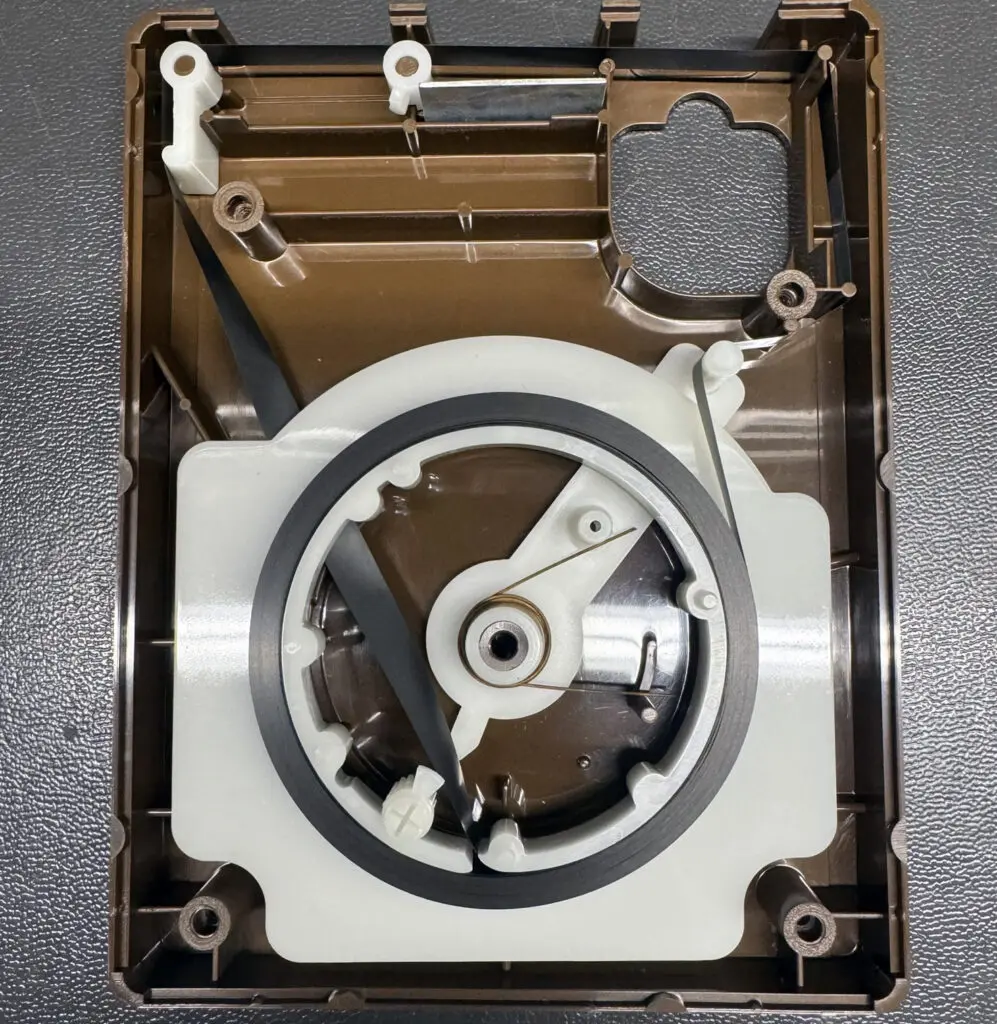

Rather than using foam rubber pressure pads to hold the tape against the heads, the ScotchCart included a tension arm within the device to maintain proper contact between the tape and the head. A closeup of the mechanism can be seen in the photo below.

This approach addressed a long-standing problem with other cartridge designs–namely, wear and deformation of the pressure pads, which tended to lose their tension over time. The ScotchCart also had a tension adjustment accessible from the top of the cartridge.

Fast-forward 30 or 40 years, getting old cartridges to work today is a bit of a challenge. For the other cartridge brands (Fidelipac and Audipak) replacement pressure pads are available via special order from 8 Track Avenue. Since the ScotchCart uses a different mechanism for holding the tape against the heads, this is not a problem. However, there is a different problem—commonly known as “sticky-shed syndrome.”

From WikiPedia: “Some tapes may deteriorate because of a breakdown in the binder (the glue) that holds the oxide particles on the tape, or the back coating on the reverse side, if the tape was from any of the tape manufacturers who had inadvertently used an unstable binder formulation. That binder contained polyurethane that soaks up water (Hydrolysis) and causes the urethane to rise to the tape’s surface. This problem became known as the “sticky-shed syndrome.”

The impact–if any–of stick-shed syndrome varies depending on the tape manufacturer and type. I have cleaned, repaired, and returned to service more than 200 NAB type cartridges and none have experienced this problem except for the ScotchCart.

I recently acquired a large quantity of ScotchCarts. After cleanup, about a third worked fine. The rest did not. The layers stick together and the tape doesn’t move at all.

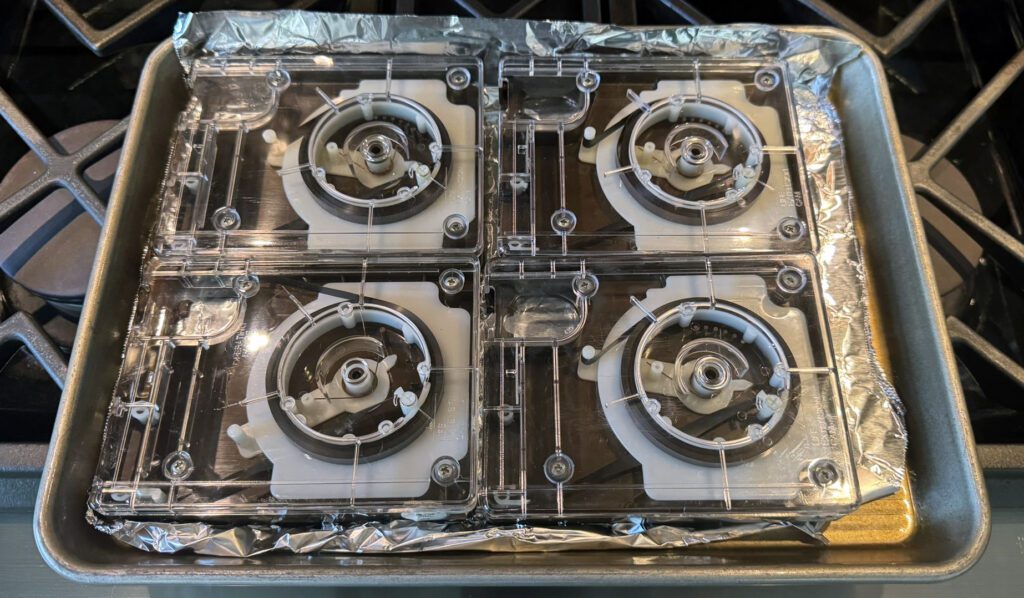

Again from Wikipedia: “Baking is a common practice for temporarily repairing sticky-shed syndrome. There is no standard equipment or practice for baking, so each engineer is left to create their own methods and materials. Generally, tapes are baked at low temperatures for relatively long periods of time, such as 130 °F to 140 °F (54 to 60 °C) for 1 to 8 hours.” This works fine for tape on metal reels, but for a cartridge made of plastic, it’s impractical.

I tried the banking approach on a selection of ScotchCarts at a temperature of about 100 degrees, but the results were uneven. Caution: if you use a temperature above 100 degrees, the cartridge shell may warp, rendering the device unusable.

After some amount of trial and error, I found the best solution was to remove the top of the cartridge and carefully applying circular pressure to the tape package in order to move the layers apart. Once that was done, I put the cart in a machine and let it run through at least one time for the full length of the cartridge. That repacked the tape. The next step was to put the tape into an eraser/splice finder to prepare it for use.

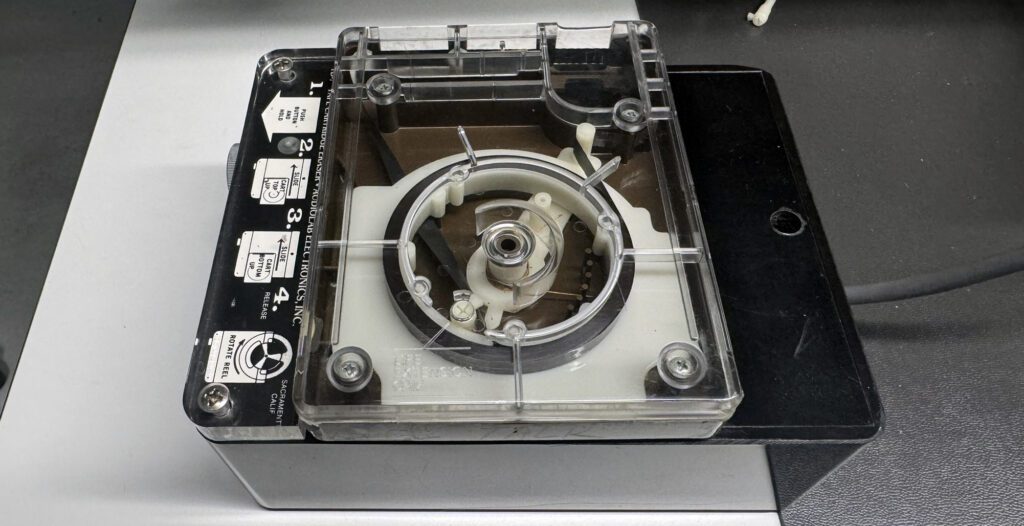

Shown above is an ITC ESL-IV eraser/splice finder machine. It is important to first run the carts in a standard machine before using the ESL because of the faster speed of the ESL winder.

While the ESL does a good job of erasing, I have found that a final pass through a tape eraser provides the lowest residual noise.

The tension adjustment noted above is labeled “Life Extension Cam” on the cover of the ScotchCart. Turn the adjustment screw counterclockwise to reduce hold-back tension and clockwise to increase it. On first use, set the screw fully counterclockwise to minimize winding resistance. As an alternative to applying pressure to the tape pack (as described above) the adjustment screw may be turned fully clockwise and then fully counterclockwise one or more times in an effort to loosen and separate the tape layers.

After the cartridge has completed at least one full pass and while running at normal speed in a cart machine, slowly adjust the Life Extension Cam so the tension arm is at about mid-travel. This works well in most cases. Remember to keep the tape heads clean, as any residue on the heads will increase tension.

With the ScotchCarts now handling tape as needed, my expectation is that with regular use the sticky-shed tape syndrome will not be a recurring problem. Fingers-crossed.

It is worth noting that most of the ScotchCarts that I reconditioned were of longer lengths (2.5 min to 3.5 min). Shorter lengths (e.g., 40 sec or 70 sec) are less likely to suffer from the sticky-shed issue. For cartridges longer than 3.5 min, the sticky-shed problem may be so severe that it is impossible to return the cartridge to service.

Another consideration is the the storage environment. Temperature extremes and high humidity presumably impact the extent of the problem. Those details are largely unknown, however.

A visitor to this site noted another potential reason for the Scotchcart sticking problem, namely that the spring-loaded tension arm ensured that the tape was tightly wound, which increased the likelihood of problems. With other cartridge types, e.g., Fidelipak, the tape pack is wound less tightly.

After reconditioning dozens of ScotchCarts and recording program material on them, I am impressed at how well these 30 or 40 year old devices work today. The audio quality is superb. There is some evidence of shedding, requiring frequent cleaning of the tape heads. All in all, however, great performance.

The carts shown above will go into three SMC Carousel cart machines that I recently purchased (see Restoring Classic Carousel Cart Machines). With proper care, these 1970s technologies keep going. And going…