Radio Studio Automation System

Having completed work on the 1970s radio studio, the next step in recreating the AM/FM station where I worked in the ’70s and ’80s was to build up a vintage automation system.

For an FM station back in the day, it was common to have programming handled by an automation system. The equipment required to accomplish this task included, but was not limited to, the following:

- A control unit to manage operation of the system and switch audio sources

- One or more multi-playback cart machines, typically a “carousel” device

- Multiple reel-to-reel playback decks, which were loaded with pre-recorded syndication tapes such as the one shown above

I had been interested in building up an automation system for some time, but work on the ’70s studio took precedence. And, I hadn’t been able to find a carousel cart machine or control system. That changed one day in a chance visit to eBay. I saw a Gates carousel cart machine for sale and acquired it. In a conversation with the seller, I found that he had a vintage Gates control unit that he was interested in selling. It came to pass that I acquired the control unit, and so the project began…

Gates SSC Switching Center

The central part of the automation system is the Digital Touch-Control SSC. This unit is the switching center and control point of the Gates KSP-10 program automation system. Nearly all of the control commands, control responses, audio programming, auditioning, logging, etc., are routed through the SSC for switching and processing.

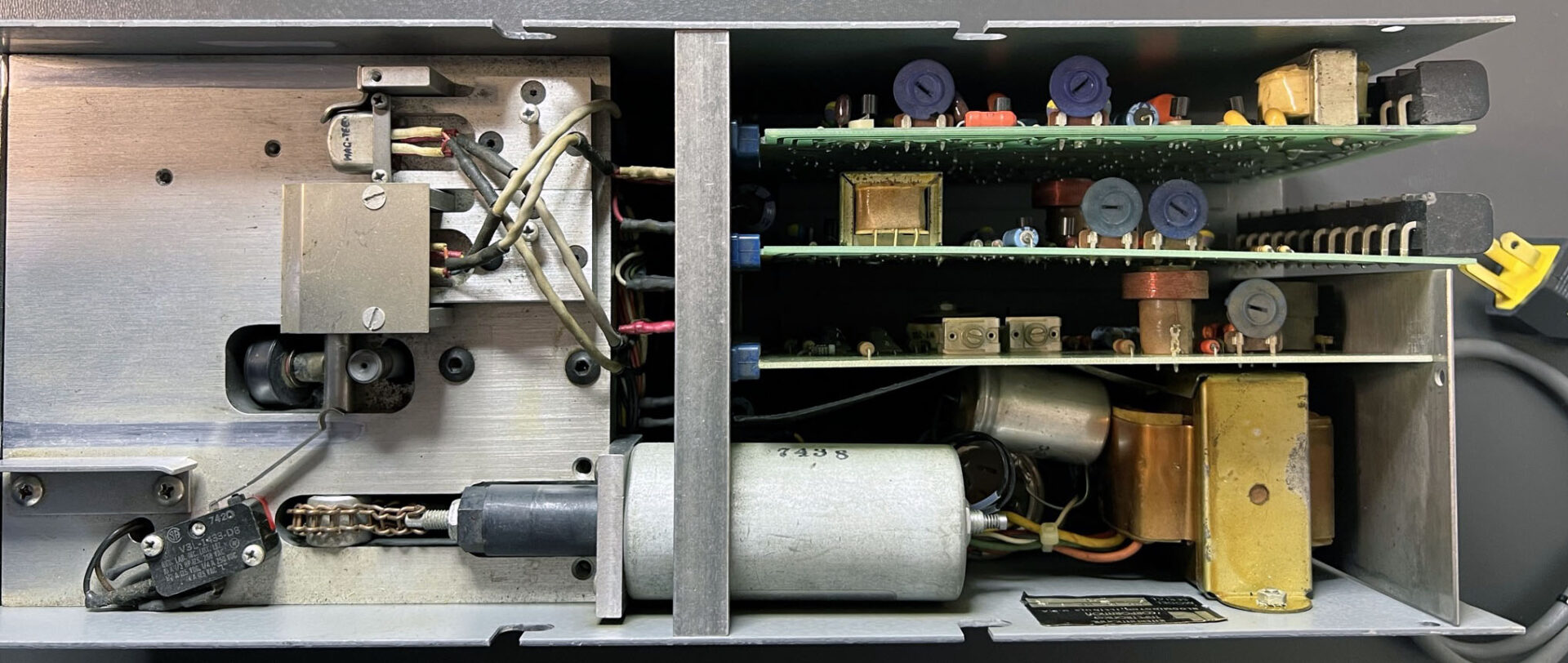

The photo below shows the SSC controller as it arrived at the beginning of the project.

The SSC System Switching Center can connect up to 10 sources to the control and output circuitry of the system. Both sub-programmer-controlled sources and main-programmer-controlled sources connect to the SSC Switcher. A nine source extender for the SSC is available for expanding the system from 10 to 19 source capability.

The rear panel of the SSC as it arrived is shown above. The unit was in generally good shape and all parts appeared to be present, including cabling to the source machines.

Following the customary clean-up, the unit was installed and checked out.

Gates KSP-10 Programmer

The Gates KSP-10 Digital Touch Control System Programmer provides fully automatic control of an automation programming system when used in conjunction with Gates SSC Switching Center. It can sequentially call on up to 10 audio sources, such as cartridge, reel-to-reel, network, remote, or audio console output. Time correction and sub-programmer block advance information may also be entered into the magnetic cartridge memory of the KSP-10. A stored event within the tape cartridge memory may be changed at any time by accessing that event and rewriting it. An entry error may be immediately corrected by following it with an ERROR entry, then rewriting it. This eliminates the necessity of reprogramming the entire memory tape because of an entry error or any desired change in programming information.

Unassigned events, time correction, and sub-programmer block advance information space may be reserved in the memory tape by entering a “Skip” event at any place desired in the memory sequence. They may be later accessed and programmed to change or expand the operating sequence. Five digits of information (source numbers, time correction entries, etc.) are stored in approximately one second of tape time. The average half hour in a Top-40 format would require almost 5 seconds of memory tape, so a typical 18-hour broadcast day can be programmed on a 3-minute cartridge.

An important verification feature of the KSP-10 permits the use of audio tape for encoding the BCD signals in the memory cartridge. Each digit must be verified by reading the recorded signal in the “write” portion of the read/write head before an entry sequence is complete. If tape drop-outs are encountered, the KSP-10 will automatically re-enter the command until full verification is received. Each incomplete entry will receive an error code as a part of the re-entry cycle, so the incomplete entry will always be skipped in the playback service.

The magnetic memory portion of the KSP-10 consists of a cartridge tape transport similar to Gates’ Criterion Compact. The front panel of the tape transport contains only an LED power indicator. Full control of the tape deck is obtained through the manual and automatic operation of the associated programming section of the KSP-10.

A photo of the Gates KSP-10 is shown above from the Gates product catalog. As is evident by the foregoing description, this unit is sophisticated and versatile—especially considering the period in which it was designed and fielded. Unfortunately, a long search for a KSP-10 for the Studio Three automation system has been (so far at least) unsuccessful. The basic functions of the KSP-10, therefore, were implemented using a different, simpler, system.

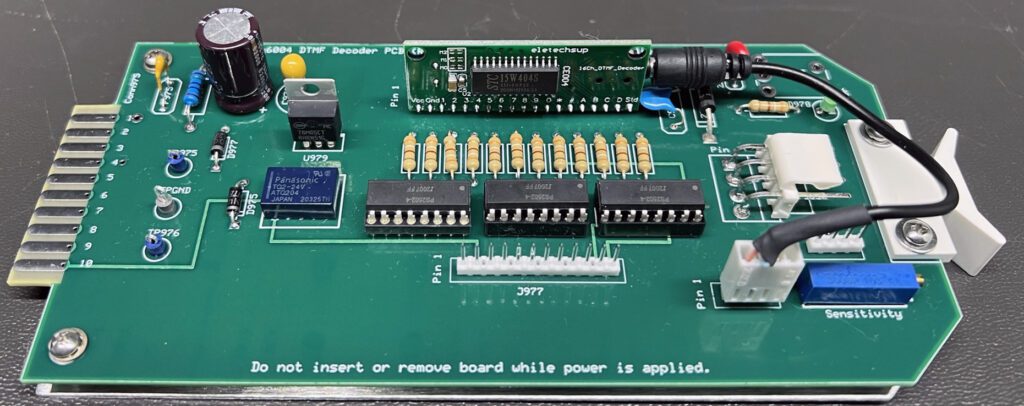

Dual-tone-multi-frequency (DTMF) tones are used to control operation of the automation system. A standard cart deck serves as the storage element. The programming functions are housed in a small desktop chassis, permitting easy operator interaction. The DTMF codes are recorded on an ITC-PD-II machine. A separate ITC PD-II play cart machine is used as the program playback device. Decoding of the tones recorded on the storage cartridge are performed by the WA-6004 DTMF Decoder, the output of which is applied to the SSC. Two cart machines are used in this application in order to allow programming to be done at the Encoding Station while the automation system is on the air. A photo of the decoder PCB is shown below. It is housed in a large card frame within one of the automation system racks. The WA-6004 provides the necessary control interface to manage playback sources on the SSC.

Three PD-II machines were purchased off of eBay—all mono. One is play-only and the other two are play/record units. All were in need of work, some mechanical some electrical. The PD-II after refurbishment is shown below. All of the units now meet their original equipment specifications.

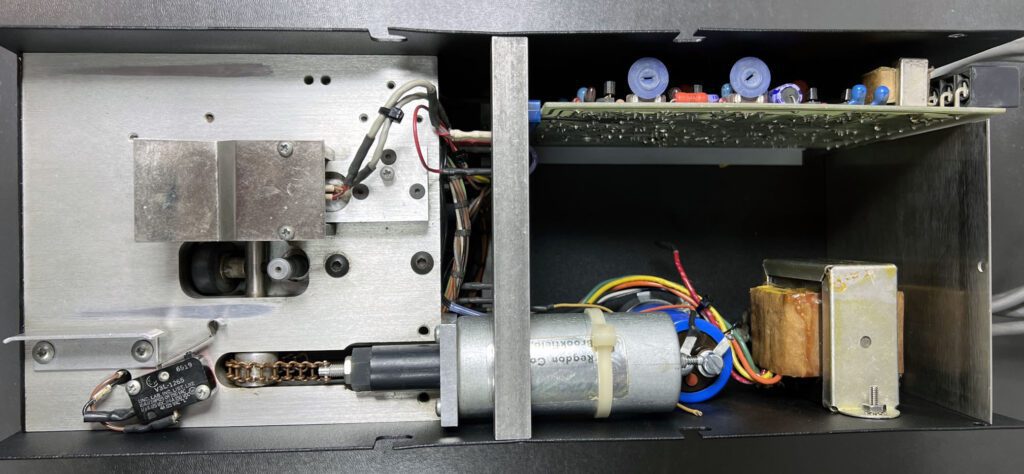

In addition to a thorough cleaning and component replacements as needed, the cabinet was refinished in a black satin textured powdercoat to match the rest of the studio gear. An internal view of the cart machine is shown below.

A gallery of photos of the ITC PD-II cart machine during the repair and restoration project is shown below.

In addition to the PD-II cart machines, an ITC Erase/Splice Locator (ESL) was acquired and refurbished. The ESL is an interesting device that identifies the splice in a tape cartridge and positions it away from the recording (music, commercials, etc.). At the same time, the ESL erases the cartridge. It is a convenient way to prepare a tape cartridge for use.

Three of the ITC machines are shown below in one of the automation system racks.

The ITC PD-II playback section does not include a secondary (EOM) tone detector. Since this functionality is required to use the cart machine with the automation system, a stand-alone 150 Hz detector was designed and built (the WA-6002), as shown below.

The PD-II includes a “cue output” terminal, which is used to drive the WA-6002 board.

Audio Control Center

The ACC-1 and ACC-2 audio control centers provide a consolidated program output and monitoring unit for the Gates program automation system. Solid-state modular amplifiers, as used in Gates studio audio consoles, provide outstanding performance, with program amplifier output capability up to +26 dBm (+8 dBm nominal), and plug-in monitoring amplifiers at 10 watts (+40 dBm) per channel.

Both the monophonic ACC-1 and stereophonic ACC-2 control centers accept 25 Hz high-pass filter(s) for use in automation systems with reel-to-reel tape audio sources. The ACC-2 stereo audio control center also provides for the installation of an optional L+R sum channel output amplifier. Power supplies and all modular amplifiers plug into the rack-mount chassis.

The audio control center front panel facilities include VU metering, monitor gain control, and meter/monitor selector switch for visually and aurally checking program output, audition, and external audio source such as an off-air monitor. In stereophonic ACC-2 units, a fifth switch position provides an accurate check of channel phasing.

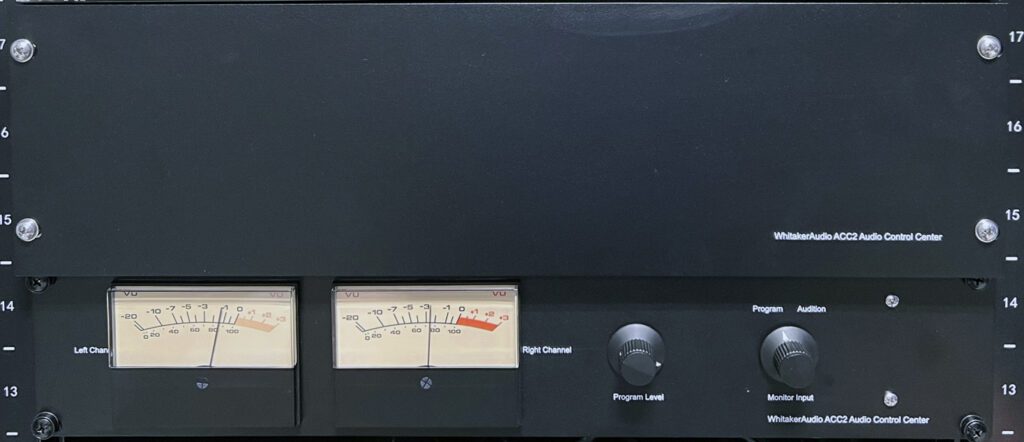

Unfortunately, an actual ACC-2 unit could not be found on eBay or elsewhere. Therefore, in this implementation the functions of the ACC-2 are accomplished with WA-6107 amplifier cards and related hardware housed in a PCB card frame. A control panel linked to the card frame permits operator interaction with the system. The WA-6107, described in the blog posting “Gates Executive Audio Console Restoration, Part 3: Further Enhancements,” is based on a design used in the Gates Executive audio console, which was produced within the same general time frame as the SSC. The controller is designated the WA-ACC2.

The audio controller functions have been reduced to essential facilities, which include Program gain, Program channel monitoring, and Audition channel monitoring.

Gates Carousel Cart Machine

The Gates G-824 Carousel tape unit is a rotary drum mechanism for tape cartridges that can be operated by manual, automatic, and random-access controllers. Each drum holds a maximum of 24 standard cartridges, and revolves to allow positioning of the cartridges against the stationary transport.

The G-824 positions cartridges in sequence unless an optional random access unit is employed. G-824 mono and stereophonic units are compatible with most radio automation systems. Modular solid-state electronics provide for the NAB standard controls of 1000 Hz, 150 Hz, and 8000 Hz cue tones In addition, logic control of the start-stop functions may be used.

Exclusive Gates features adapted from the Criterion 80 cartridge machine for improved reliability include the microset head assembly and vapor-blasted large diameter capstan drive for increased torque and superior audio reproduction.

Cartridges in the G-824 can be randomly played with optional accessories. A manual remote control or a random-access programmer for automated use are also available.

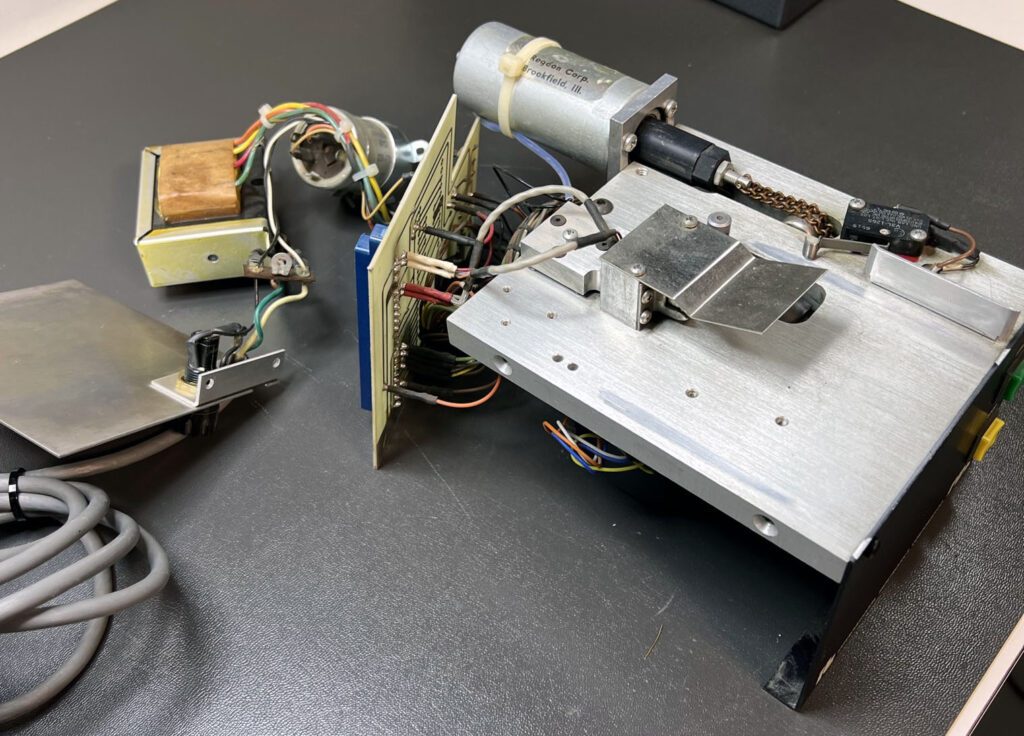

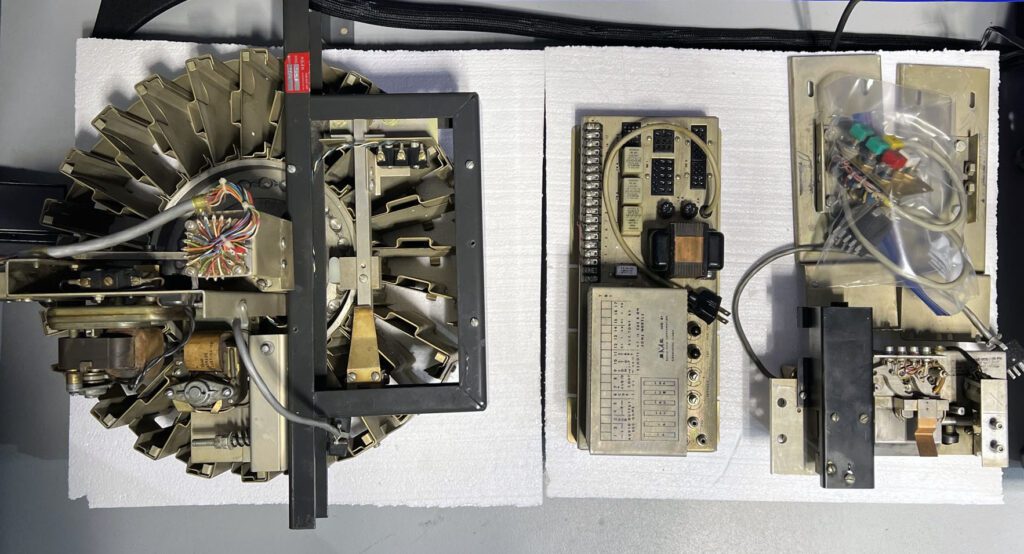

The Carousel machine that I purchased on eBay was in generally good condition when received. The machine was divided into four major subassemblies for shipment, as shown below.

The front trim panel was removed and sent off to be refinished by a powder-coat vendor.

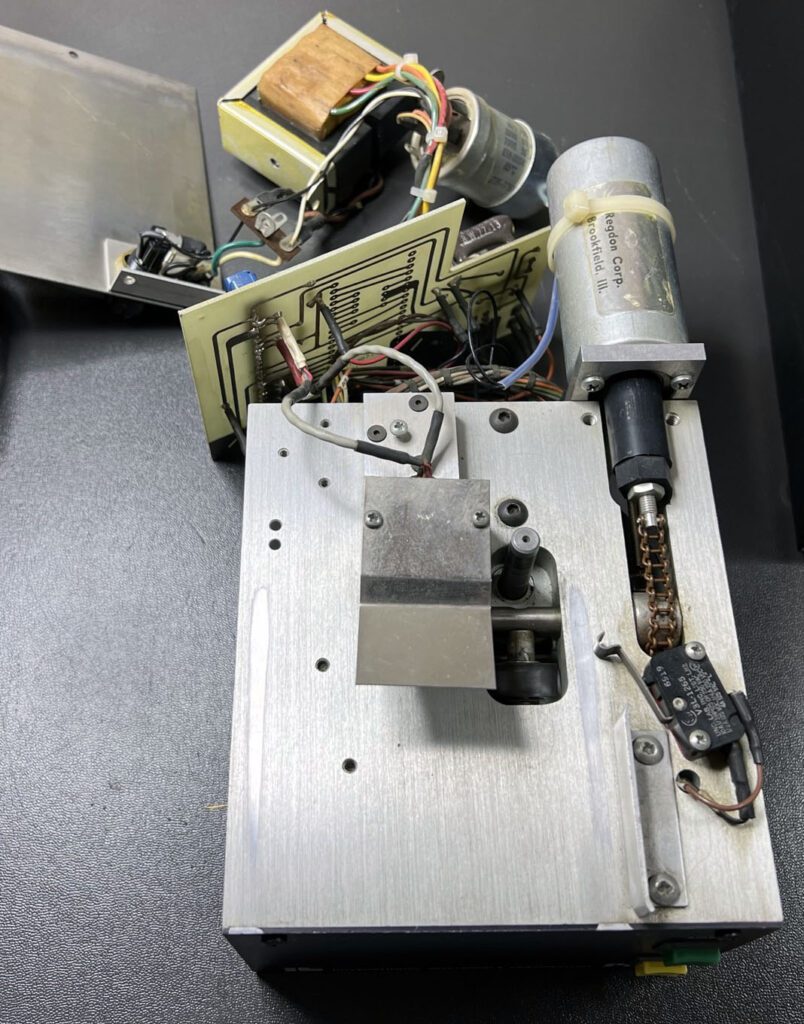

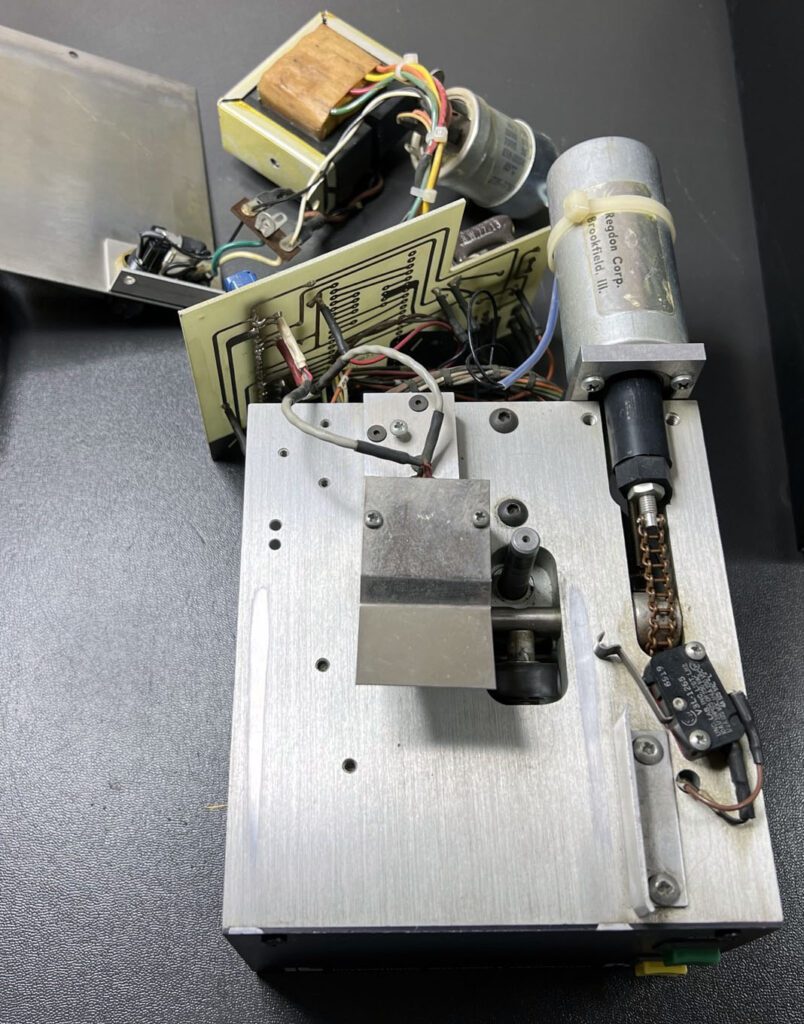

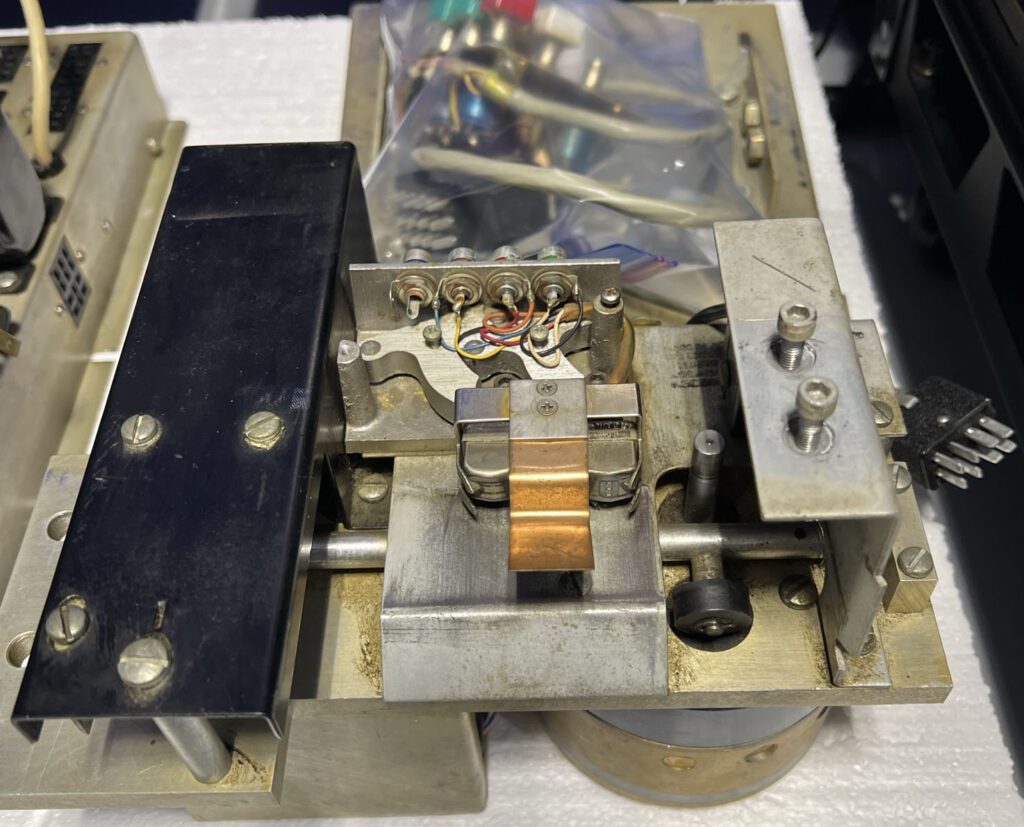

The transport tape mechanism, shown below, was in good shape, although considerable disassembly was needed to thoroughly clean and check the unit.

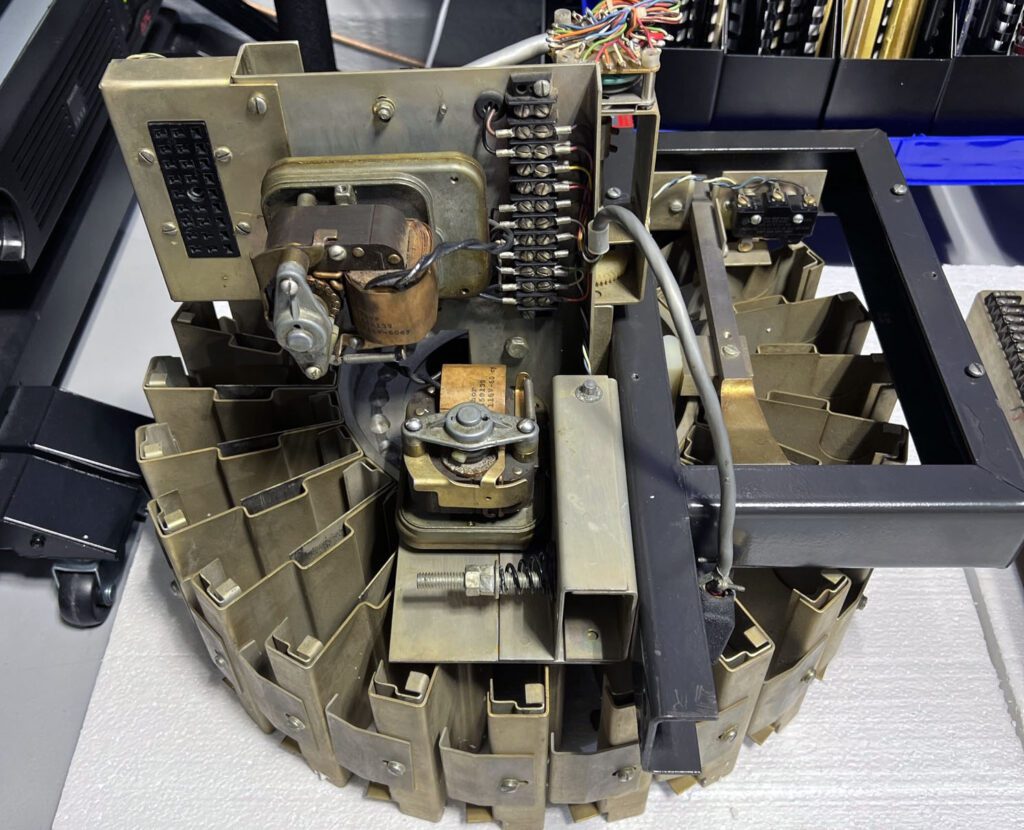

Three motors are used in the machine. One is for the tape transport (shown above) and the other two are used to move the cartridges and drum (shown below). All three motors were removed and thoroughly cleaned.

The carousel cart machine is quite heavy and access to components is a challenge after the unit is installed in the rack. All of the detailed work, therefore, was done before reassembly.

The photo below shows the Carousel cart machine as installed in the automation system rack.

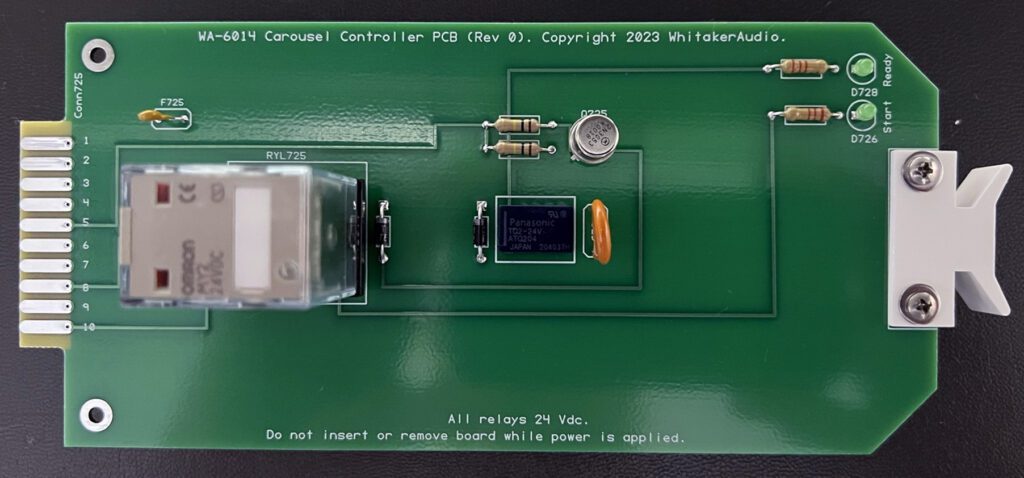

The SSC controller requires a “ready” signal to be present at any source input before the system will put the source on the air. In order to provide this signal, it was necessary to design an interface board, as shown below.

After installation of the Carousel machine, performance tests were run to confirm that the device met original equipment specifications.

Audio Source Machines

In addition to the G-824 Carousel cart machine, four additional audio sources are provided in this implementation:

- Ampex AG-440 stereo reel-to-reel tape deck (quantity = 2)

- ITC PD-II playback cart machine

- External audio (network, console output, etc.)

As noted previously, the SSC system can accommodate up to 10 input sources in the basic configuration.

The PD-II cart machines, as described above, were in generally good condition when they arrived. However, the first of two AG-440 tape deck, also purchased on eBay, was a mess. The eBay ad described the unit as “clean” but it was far from that. In fact, I don’t believe that I ever received a piece of hardware with so much dirt. Cleaning began right out of the box and was done outside so as to not mess up the shop. In desperation (and clearly a kill-of-cure move), I used a garden hose to wash off the machine. (Never done that before.) Fortunately, it was warm day and the deck quickly dried.

The AG-440 after cleaning is shown below.

With the AG-440 cleaned-up and in the shop, an assessment of the scope of the project was possible. For starters, both reel motor shafts were bent, rendering them unusable. Fortunately, a search on eBay turned up a pair of NOS reel motors for a reasonable price. The reel turntable pads had long since deteriorated, but replacements are available from Full Track Productions of Seattle. The pinch roller also needed replacement, but here again, new units were available from Full Track Productions.

From the photo above, it is clear that the tape head cover was non-functional. Also, the take-up reel tension arm was corroded. Despite all of the problems with this machine, it was returned to near-new condition after a considerable amount of work. The unit after refurbishment is shown below.

The second AG-440 tape machine was in much better shape, requiring only cleaning and adjustment. That was a relief!

Programming for classic radio automation systems is typically provided on pre-recorded reel-to-reel tapes. These tapes include a 25 Hz sub-audible tone to indicate the end of the program element (end-of-message, EOM). The tone signals the automation system to advance to the next program element. Most tape decks do not include the required 25 Hz tone filter, detector, and related machine control functions. Therefore, separate devices are required. For this implementation, the following boards are used:

- WA-6003 sub-audible filter, which filters the audio output of the tape deck to remove the 25 Hz signals.

- WA-6006 EOM detector, which senses the 25 Hz EOM tone and closes a relay to signal the automation system.

WA-6015 AG-440 interface, which places the tape deck in the Stop mode after the EOM is detected.

An adjustable delay is provided to accommodate various pre-recorded tape formats.

These PCB, and other interface boards, are included in a large card frame, shown below.

The 25 Hz EOM tone is typically recorded only on the left channel. However, the left and right outputs of the tape deck are applied to individual WA-6003 sub-audible filter boards in order to maintain the proper stereo image. This is necessary because the filter introduces some amount of phase shift, which—while small—can nonetheless impact the stereo image.

For the implementation envisioned by the Gates SSC automation system (as described above) the ACC control unit can accommodate a 25 Hz low-pass filter to remove the EOM tones present on prerecorded tapes. In the implementation described here, only the tape deck outputs are run through sub-audible filters. While more complex, this approach eliminates the inevitable loss of low frequency response for audio sources that do not need filtering, such as tape cartridge machines (Carousel and single-play), network feeds, and turntables.

All hardware for the automation system described here is housed in a 3 rack assembly, as shown below.

The first rack (far right) holds the Gates SSC controller, ITC cart machines, PCB card frame, monitor speaker, and a server for connecting with the rest of the world. The center rack holds an Ampex AG-440 tape deck, turntable, patch bays, auxiliary equipment, monitor speaker, cue speaker, and Audio Precision System One test set. The third rack (far left) holds another AG-440 deck, the Carousel cart machine, Soundcraftsman AM/FM tuner, UPS power supply, and monitor speakers.

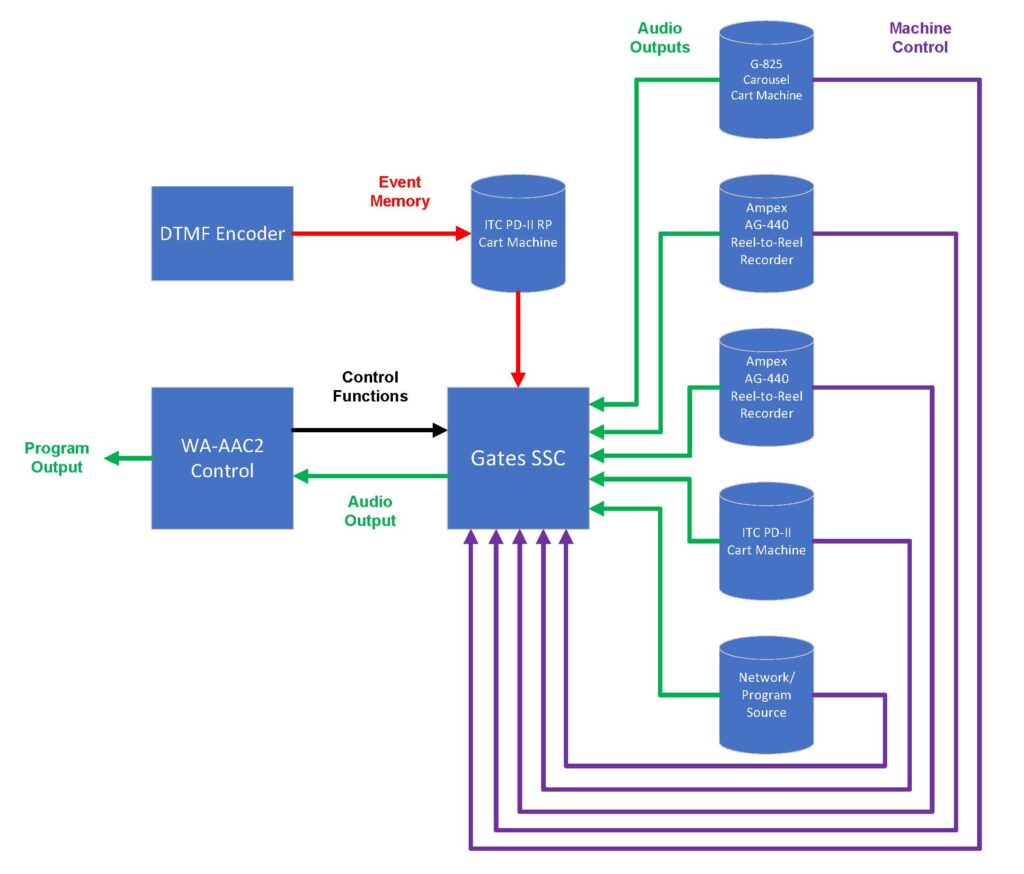

A functional block diagram of the system is shown below.

A functional line drawing of the Studio Three automation system illustrates the interconnection of major elements.

The full equipment list for the automation system is as follows:

- Gates SSC automation controller

- WhitakerAudio WA-ACC2 audio controller

- Two ITC PD-II cartridge tape decks; one play, one record/play

- Digital audio workstation with Digigram VX222-V2 sound card

- ElectroVoice EV-100A studio monitors (quantity = 2)

- Ampex AG-440 stereo tape decks (quantity = 2)

- Gates G-824 Carousel tape unit

- Soundcraftsmen ProTuner Four AM/FM Stereo tuner

- M-Audio monitor speakers (quantity = 3)

- Hitachi HT-R10 turntable with WA-6169 phono preamplifiers

- ADC 96 point Type TT patchbay

- LINKCOMM 24-bay shielded RJ45 patch panel for telco interface

- XLR patch panel for mic-level sources

- Audio Precision System One test set

- WhitakerAudio WA-6031 audio oscillator

- WhitakerAudio WA-6110 cue/dim controller

- Three-level card cage for interface PCBs

- Western Electric rotary telephone

- ITC ESL cartridge preparation station

- APC UPS systems (quantity = 2)

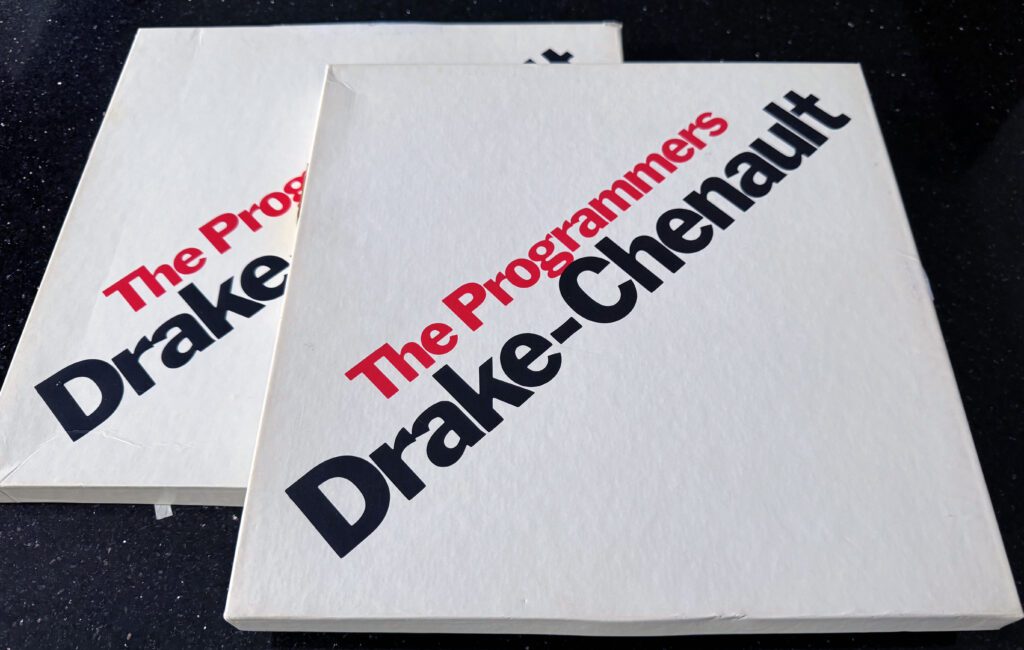

Vintage source material for the reel-to-reel tape decks was acquired on eBay. Two sets of tapes were found: Bonneville International “easy listening” and Drake-Chenault “classic rock.” Cartridges for the Carousel cart machine were also purchased from eBay. All were cleaned and refurbished, and then recorded with classic rock selections. Several carts were also recorded with commercials from the 70s and interstitials from a local station, giving the automation system playback an authentic “70s sound.”

Documentation for the Studio Three automation system is available on the Available Downloads blog. A printed copy of the installation is available from the Available Printed Documents blog.

This was a big project, stretching over a year from acquisition of the hardware to completion of a working system. It took on a life of its own, but turned out very well.

(Note that the product descriptions above are based on information contained in the Gates literature.)